Home> Products> Digital Press> IQ-501 Intelligent Quality Optimizer

IQ-501 Intelligent Quality Optimizer

KEY FEATURES

Density balance auto adjustment

Gray balance adjustment for exact color

Front-to-back automated registration

Streamlines your process

Real-time tone management controls

Printer calibration and profiling

About

-

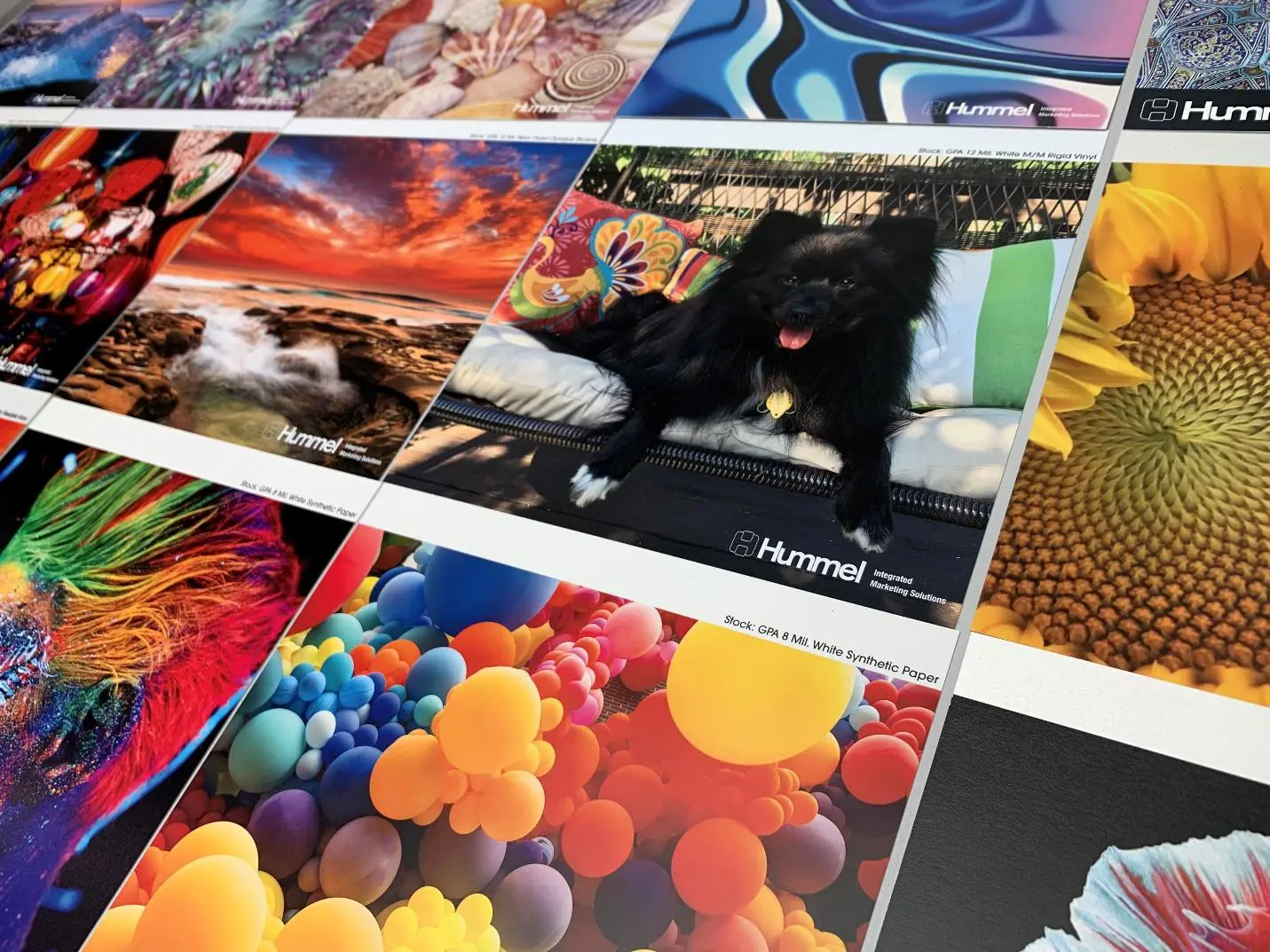

Our new IQ-501 Intelligent Quality Optimizer takes color consistency and registration accuracy to the next level. With highly automated image registration and color control, a closed-loop system that constantly monitors and adjusts printed output, and automated color calibration and profiling, IQ-501 Intelligent Quality Optimizer delivers streamlined operator time, reduced print waste, and industry-leading productivity! This is currently available on our AccurioPress C14000/C12000, C2070/C2070P, C3080/C3080P, C3070, C6100, C6085, 6120, 6136, and 6136P models.

-

Automated color and registration adjustment before the first sheet is printed

What used to be manual processes to control density, tone, color, and registration values have become as simple as the push of a button with IQ-501, reducing operator time and wasted output

Excellent print quality from even your newest press operators

This Intelligent Quality Optimizer ensures that even your less experienced press operators will be able to produce precisely registered, calibrated, and profiled color prints, on the first run and on every run. IQ-501 is your key to minimizing labor costs without compromising the print quality your customers demand

Real-time color and registration adjustment

Continuous monitoring and closed-loop, automated process controls ensure that every print is checked and on-the-fly adjustments are made to ensure only the highest-quality color and registration results for you and your customers.

AccurioPro Cloud Eye fleet connectivity

IQ-501 Intelligent Quality Optimizer works seamlessly with AccurioPro Cloud Eye, enabling consistent registration, calibration and profiling among a fleet of IQ-501 equipped presses.

-

Printer calibration and profiling

To get the best quality from the print engine, a calibration and ICC profile should be created for each new media. This can be a manual, labor intensive process.

Front-to-back automated registration

Specify the media and tray, and the front-to-back registration will be automatically adjusted for the job, page by page, to control both vertical/horizontal orientation as well as image skew.

Density balance auto adjustment

Any uneven density values are automatically detected and corrected with the IQ-501.

Real-time tone management controls

Continuous check-and-correct algorithms ensure smoother skin tones and gradations. Packaging, tags, business cards, high-density images, and colorful tints are rendered richly and accurately through density optimization.

Gray balance adjustment for exact color

If you’re printing mono pieces or image elements using CMY process grays, any deviation from the reference color is automatically monitored and corrected as you print for both linearization and gray balance.

Streamlines your process

The IQ-501 prints, reads, and measures sheets, then collects and stores the measured values for that stock automatically, reducing a typical profiling time from a 30 minute task to 5 minutes or less.

Digital Print is our Genetic Code

Fiery Command WorkStation

Fiery® Command WorkStation®, the most popular print management software in print production environments, is the central hub for managing multiple printers and print jobs within an organization across brands, locations, and printer types.

Enhance performance. Increase productivity

Fiery offers two external digital front ends (DFEs) – Fiery MIC-4170 and MIC-4160 – for the black-and-white Konica Minolta AccurioPress 6120/6136/6136P/7120/7136/7136p digital presses, and the MIC-4170 for the AccurioPress 6272P. Based on the Fiery FS500 Pro platform, Fiery MIC-4170 and MIC-4160 external servers are targeted toward high-volume monochrome production environments.